Chip mounting equipment introduction

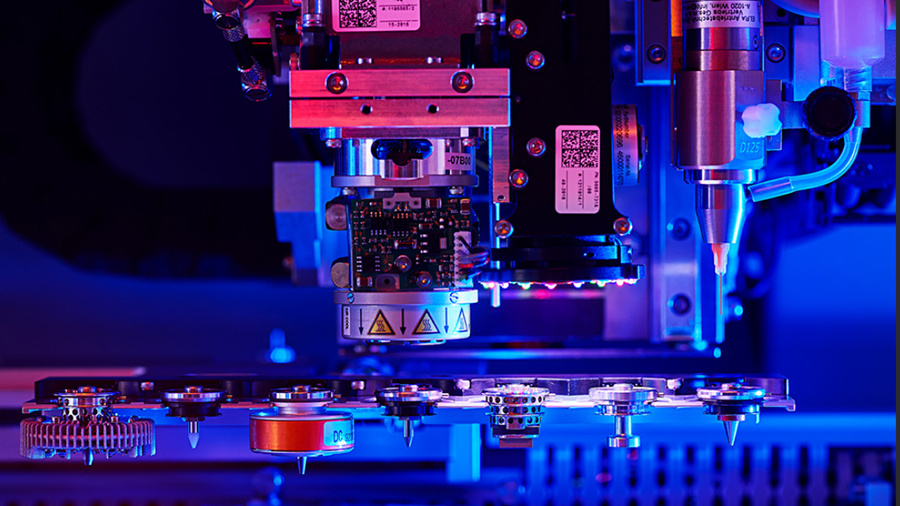

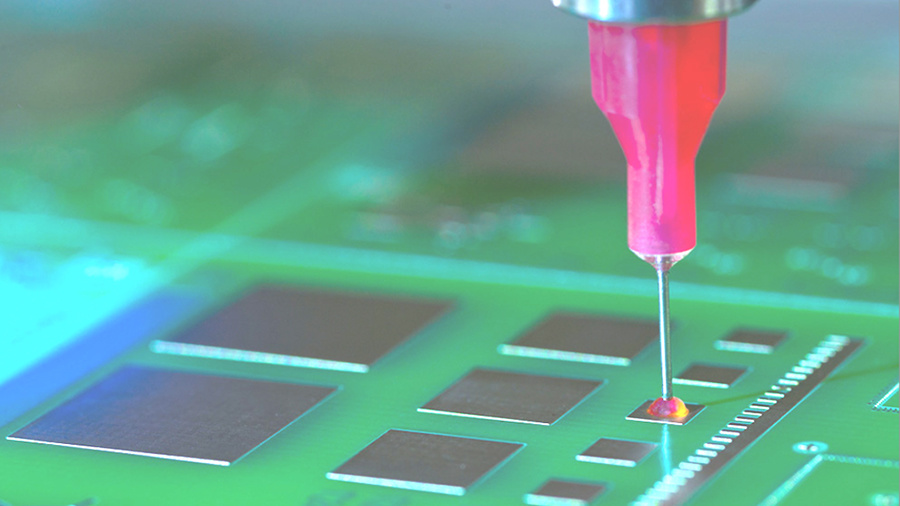

Datacon 2200 evo Advance

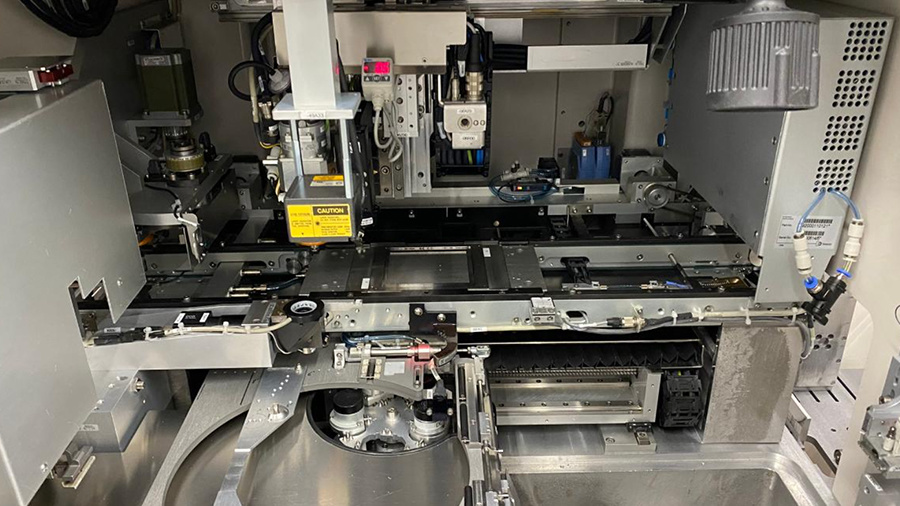

The Datacon 2200 evo high precision multi-die bonder offers extreme flexibility for die attach and flip chip applications. Equipped with an integrated dispenser, 12" wafer handling, automatic tool changer and application specific tooling, the Datacon 2200 evo meets current and future process and product requirements.

High Precision and Excellent Performance

• High-precision positioning: 3μm positioning accuracy

• Advanced visual alignment system: Improves positioning accuracy

• High-precision camera imaging: Accurately identify and adjust chip position

Intelligent and Automated Features

• Intelligent control system: reduces the complexity of manual operation and improves production efficiency

• Automated monitoring and feedback: helps users to find and solve problems in time, ensuring the quality of die bonding and production efficiency

• Integrated automation solution: integrates with other automation equipment and systems to form a complete automated production line

Efficient Production and Flexibility

• High productivity and throughput: Complete the packaging tasks of a large number of chips in a short time

• Flexible configuration and customization capabilities: To meet the specific needs of customers

• Multi-chip processing capabilities: Process chips of multiple types and specifications at the same time, improving the applicability and flexibility of the equipment

Stable, Reliable and Easy to Maintain

• Stable and reliable mechanical performance: helps reduce equipment failure rate and improve production efficiency

• Easy maintenance and care: reduces equipment maintenance costs and extends equipment life

K-Hiragawa Photonics Technology (Suzhou) Co., LTD

Email:kh-photonics@sz-hiragawa.com

Address:No. 18, Qinfeng North Road, Qiandeng Town, Kunshan City, Suzhou City, Jiangsu Province

©2025 K-Hiragawa Photonics Technology (Suzhou) Co., LTD All rights reserved.SEO Designed by:www.300.cn